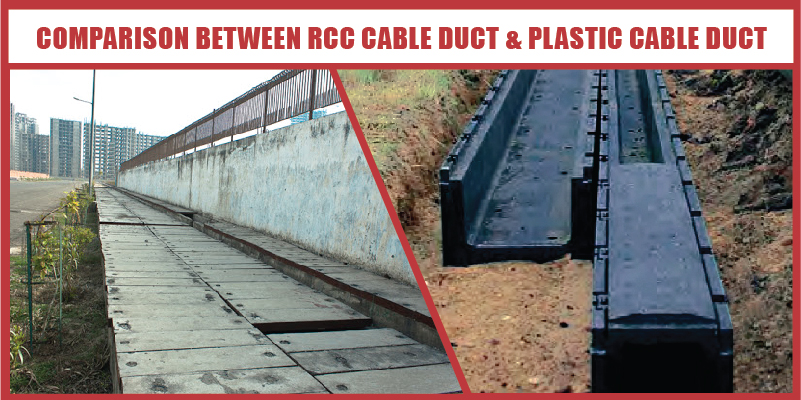

Essentially, ducting is to protect signaling, telecommunication and electrical cables. It is necessary when power transmission or data exchange is under consideration as it demands higher reliability and minimum influence from whole range of external environmental factors causing wear and tear of the cables.

Cables should never be laid directly without any protective covering as it is hazardous for people and machinery who may come into contact with it and the supply running through it. Conventional techniques such as concrete cable trays, full round plastic or GI Pipes does not meet the basic design requirement to withstand the rigors of externalities environmental and extreme load conditions. Using right type of ducting and correctly installing the cables in them ensures the safety of cables and the supply that passes through these cables.

JMV has developed injection molded plastic cable ducts using special polymers called polyolefin and designed specifically to stand up to any harsh environmental conditions and has extreme load bearing capacity. Below are the reasons to avoid cable laying in RCC duct and go for plastic cable ducts –

- Polyolefin cable channel / injection molded cable duct ideal for the placement and maintenance of any type of cables and pipes are made of chemically inert material ensuring greater insulation attributes from external influences.

- Unlike heavy and bulky RCC duct, they are light in weight yet strong in nature. Moreover, its honeycomb design gives better dimensional stability.

- Owing to its weightless attribute, it is easy to replace, repair, transport and store which require less labor.

- Available in different sizes to accommodate any number of cables. Also, cable markers can be provided at specific distances in order to identify cables for various circuit.

- Using plastic cable ducts improves scalability by simplifying cable movement, addition and changes.

- It is easier and safer to handle, install and requires no special technique/ provision/ instruments for its installations or jointing the ducts.

- This maintenance free solution has high mechanical strength and can withstand heavy load up to 12kN.

Plastic cable ducts are a replacement to RCC ducts and is normally recommended by professional contractors so as to achieve a clean and proper cable management system improving physical appearance, cable traceability, and reducing troubleshooting time while reducing the risk of human error as well.