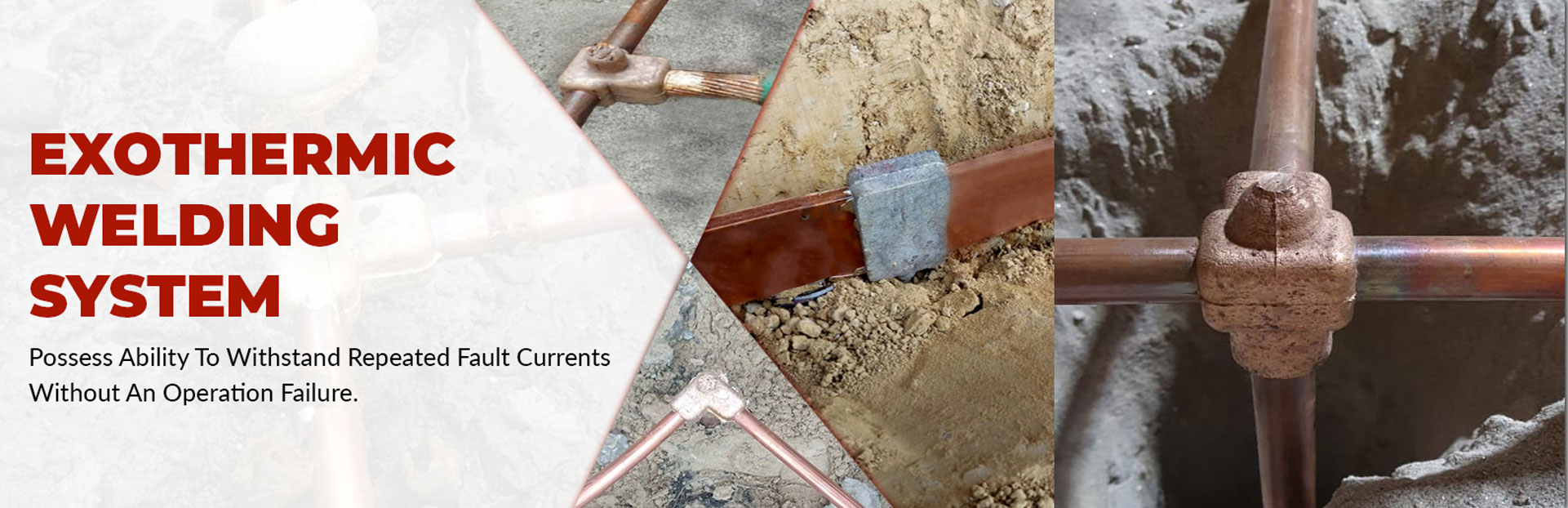

An Exothermic welding system in which a copper based exothermic welding powder, graphite mold, and exothermic welding kit together forms an exothermic weld joint in any shape or with any material of conductor as per the requirement in order to fix the jointing permanently.

HOW IS THIS RELIABLE?

Conventionally, there are many methods for jointing like bolting, welding, clamping, brazing, crimping etc. but they all don’t provide 100% contact surface area in order to form perfect connectivity through jointing. Due to lack of 100% contact surface area, oxidation occurs between the jointed conductors and corrosion starts occurring on them resulting in the failure of joint.

On the other hand, the exothermic welding system provides a 100% contact surface area along with a 1083◦ C temperature sustainable capability. Also, in the case of other joint methods, the connection gets loosen after some time but in exothermic, it’ll remain the same with time.

The exothermic welding system complies IEEE 837 standard that shows it’s a robust solution for the jointing problems. In today’s world, it is accepted as the globally remarkable method in which consumers can rely upon without any worries. This built the unbreakable bond between two or more conductors and this is a highly portable technology that doesn’t require heat from external sources to compose a joint between metallic conductors.

The bond formation can be accomplished in any type of material except Aluminium. Thus, it is the best method to be accepted for bimetallic connections. An exothermic welded connection shall be appropriate for disclosure to the components of direct burial in earth or concrete without degradation over the lifetime of the grounding system.” This technology is highly recommended by NBC 2016, IEEE 80 for all the underground earthing connections.

TECHNICAL FEATURES

It helps to form a strong bond around the conductors with satisfying conductive.

Standard exothermic weld has a cross-section higher than that of the conductor to be linked the weld will forever remain cooler than the conductor under fault circumstances.

The conductors attain superior electrical conductivity through exothermic welding.

It is anti-corrosive in nature.

There is no issue of oxidization while using exothermic welding.

It is water-resistant.

Exothermic welding can easily stand the repeated electrical discharges.

It has no harmful effect on the environment.

Exothermic welding has higher mechanical strength during bond formation in jointing.

Mainly, the critical electrical jointing or connection can be formed easily by using an exothermic welding system in order to provide long-term stability. Even after the passing time, it’ll perform remarkably well and doesn’t require any maintenance.